In an economic downturn, many businesses face significant challenges that can threaten their survival. However, with the right strategies, manufacturing businesses can not only weather the storm but also achieve growth. Resilience, innovation, and strategic planning are key to thriving in difficult economic times. This article explores various approaches that manufacturing businesses can take to grow even when the economy is struggling.

Embracing Innovation and Technology

One of the most effective ways to ensure growth during economic downturns is by embracing innovation and technology. Investing in new technologies can improve efficiency, reduce costs, and open up new revenue streams.

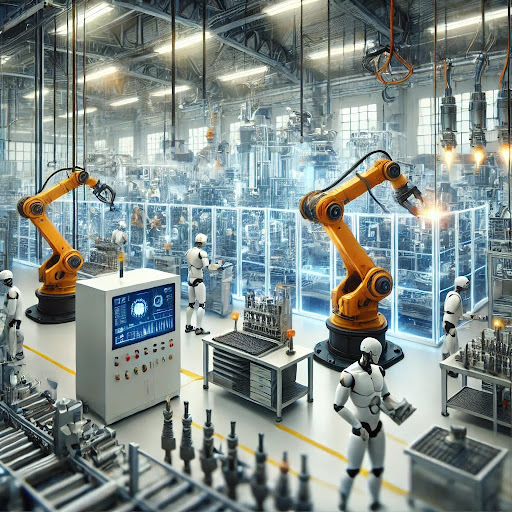

Automation and Robotics

Automation and robotics can significantly enhance productivity and reduce labor costs. Implementing automated systems for repetitive tasks allows human workers to focus on more complex and value-added activities. This not only improves efficiency but also reduces the risk of errors.

Advanced Manufacturing Techniques

Adopting advanced manufacturing techniques such as additive manufacturing (3D printing), computer numerical control (CNC) machining, and the Internet of Things (IoT) can provide a competitive edge. These technologies enable greater customization, faster production times, and real-time monitoring of manufacturing processes.

Digital Transformation

Digital transformation involves integrating digital technologies into all areas of a business. This includes using data analytics to make informed decisions, adopting cloud computing for scalable IT infrastructure, and leveraging artificial intelligence for predictive maintenance and quality control. Digital transformation can streamline operations and improve overall business agility.

Diversifying Product Lines and Markets

Diversification is a critical strategy for mitigating risk and driving growth during economic downturns. By expanding product lines and entering new markets, manufacturers can reduce their dependence on a single revenue source.

Expanding Product Offerings

Introducing new products that cater to changing market demands can help capture additional revenue streams. This could involve developing complementary products, exploring niche markets, or innovating existing products to meet evolving customer needs.

Entering New Markets

Geographical diversification can also help spread risk. Exploring international markets or targeting underserved domestic regions can open up new growth opportunities. Conduct thorough market research to identify regions with high demand for your products and develop tailored strategies for market entry.

Strategic Partnerships

Forming strategic partnerships with other companies can provide access to new markets and technologies. Collaborations with suppliers, distributors, or even competitors can result in mutually beneficial outcomes. These partnerships can help reduce costs, share risks, and accelerate innovation.

Enhancing Customer Relationships

Strong customer relationships are essential for business growth, especially during challenging economic times. Focusing on customer satisfaction and loyalty can lead to repeat business and positive word-of-mouth referrals.

Improving Customer Service

Providing exceptional customer service can differentiate your business from competitors. Invest in training for customer service representatives, implement efficient communication channels, and respond promptly to customer inquiries and concerns. Happy customers are more likely to return and recommend your business to others.

Customized Solutions

Offering customized solutions tailored to individual customer needs can enhance satisfaction and loyalty. Work closely with clients to understand their specific requirements and develop products or services that meet those needs. Personalization can create a competitive advantage and drive long-term relationships.

Lead Generation for Manufacturers

Effective lead generation for manufacturers involves identifying potential customers and nurturing relationships to convert them into loyal clients. Here are some strategies:

Content Marketing: Create valuable content that addresses the needs and challenges of your target audience. Blog posts, whitepapers, and case studies can attract potential leads and establish your expertise.

Social Media Engagement: Use social media platforms to connect with potential customers, share industry insights, and showcase your products. Engaging with your audience can build brand awareness and generate leads.

Email Campaigns: Develop targeted email campaigns to nurture leads through the sales funnel. Provide relevant information, offer promotions, and keep prospects informed about new products and updates.

Industry Events: Participate in trade shows, conferences, and webinars to network with potential customers and showcase your offerings. These events provide opportunities to generate leads and build relationships.

Improving Operational Efficiency

Operational efficiency is crucial for maintaining profitability during economic downturns. Streamlining processes and reducing waste can lower costs and improve overall productivity.

Lean Manufacturing

Lean manufacturing focuses on minimizing waste and maximizing value. Implementing lean principles such as Just-in-Time (JIT) production, continuous improvement (Kaizen), and value stream mapping can help identify inefficiencies and eliminate non-value-added activities. Lean manufacturing can enhance operational efficiency and reduce costs.

Supply Chain Optimization

Optimizing the supply chain is essential for ensuring timely delivery of raw materials and finished products. Build strong relationships with reliable suppliers, implement inventory management systems, and leverage technology for real-time tracking and forecasting. A well-optimized supply chain enhances your ability to meet customer demands and maintain high levels of service.

Energy Efficiency

Investing in energy-efficient technologies and practices can reduce operational costs. Conduct energy audits to identify areas for improvement, upgrade equipment to more energy-efficient models, and implement sustainable practices such as recycling and waste reduction. Energy efficiency not only lowers costs but also contributes to environmental sustainability.

Investing in Workforce Development

A skilled and motivated workforce is essential for business growth. Investing in employee training and development can improve productivity, innovation, and job satisfaction.

Training Programs

Develop comprehensive training programs to enhance the skills and knowledge of your employees. Offer opportunities for continuous learning, certification programs, and cross-training to ensure a versatile and capable workforce. Investing in employee development can lead to increased productivity and reduced turnover.

Employee Engagement

Fostering a positive work environment and promoting employee engagement are vital for retaining top talent. Recognize and reward employees’ contributions, encourage open communication, and create a culture of collaboration and innovation. Engaged employees are more likely to be productive, loyal, and committed to the company's growth.

Safety and Well-being

Prioritize the safety and well-being of your employees. Implement robust safety protocols, provide necessary protective equipment, and promote a healthy work-life balance. A safe and healthy workforce is more productive and resilient, contributing to overall business success.

Conclusion

Growing a manufacturing business during difficult economic times requires resilience, innovation, and strategic planning. By embracing technology, diversifying product lines and markets, enhancing customer relationships, improving operational efficiency, and investing in workforce development, manufacturers can not only survive but thrive. Adapting to changing market conditions and proactively addressing challenges will position your business for long-term success, regardless of economic fluctuations.